Powdered, Solid, & Granular materials have been commonly managed, by mechanical conveying instruments such as belt Powder conveying/Material Conveying/screw conveyers/goods lifts/bucket elevators, etc.

This fresh vision is driving the solids airborne, in a fluid state, with the use of air or idle gas traversing in a latched pipeline. The concept was found extremely appealing due to a sealed pipeline conveying & was picked up by most industries for the managing of solids pneumatically, from the last 3 decades.

Depending upon the product's characteristics, volume & air forces are applied at the configuration stage. These parameters categorize the systems as either DILUTE / LEAN Phase Conveying System or Dense Phase Conveying System.

As a leading manufacturer of Powder conveying Systems in India, we use recent technology for manufacturing Powder conveying Systems in Ahmedabad city – the business junction of Gujarat. TECHFLOW is one of the most entrusted and reliable names When it comes to high-quality Powder conveying Systems in Gujarat.

Discover moreTECHFLOW is one of the frontiers manufactories of a Powder conveying Systems. Powder conveying Systems are comprehended as Foundry Sand Transporter, material transporter, and Pneumatic Transporters. The Powder conveying system is used for conveying material from the start to numerous or single destinations with the support of compressed air. These methods employ higher force with lesser air volume per kilogram of weight conveyed as compared to the LEAN phase system. Solids in powder form have a more significant fluidisability hence the same is conveyed with this sort of powder conveying system. The pipeline mainly has a denser solid element floating in the air. That is why it is named DENSE PHASE.

Powder conveying Systems are classified as CONTINUOUS TYPE and, PLUG TYPE, as per the movement of the solid kind in the pipe.

Medium to elevated forces are needed for conveying like this, so Dry and compressed air is utilized as the primary moving force.

Conveying paces are designed relatively lower & under 5 meters/sec. Yet, initiating forces sometimes overextend 3 to 4 Bar grew commensurate with the spaces to be transmitted & system resistance. The pipe diameters are formed as per the consequent requirement & and work out relatively smaller.

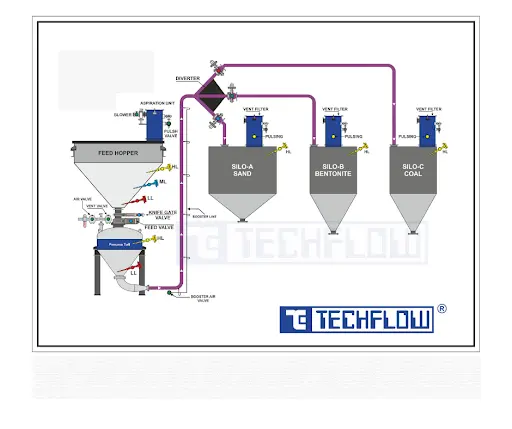

A pressure vessel is kept to acquire & transport the powder material. A terminal pulse-jet filter is kept to drain the conveying air. A pack of compact air valves & sensor systems primarily come formed on the vessel. A primary repository feed hopper is held above the vessel with an isolating Dome Tuff in between. An electrical control panel with a PLC agenda is equipped to operate the cycles of CONVEYING and FILLING.

These are the following types of Dense Phase Powder conveying Systems TECHFLOW deliveries-

High-quality powder conveying systems are manufactured in Ahmedabad. As a result of our focus on quality, we are one of the finest Pneumatic Conveying Systems manufacturers in Gujarat. Over a period we have constructed a reputation as the most dedicated manufacturer of Pneumatic Conveying Systems in India.

The Powder conveying system for the dense phase has attained vogue as its proper method to move brittle, abrasive, and hard materials at a gradual speed. It pushes material along an enclosed pipe, in a plug form, utilizing tiny amounts of gas, at a lower speed but medium and improved pressure. Powder conveying systems have periodic wearing parts which contribute to the least maintenance. Also, the production expenses help as there is low material degradation, specifically when conveying fragile materials. Techflow is a supreme manufacturer of Powder conveying systems for the dense phase in India, which provides grade-engineered supplies and is in rising need across the industries.

| Powder Conveying System Application | ||||

|---|---|---|---|---|

|

|

|

|

|

| Powder Conveying System Options | |||

|---|---|---|---|

|

|||